Categories

The latest content

-

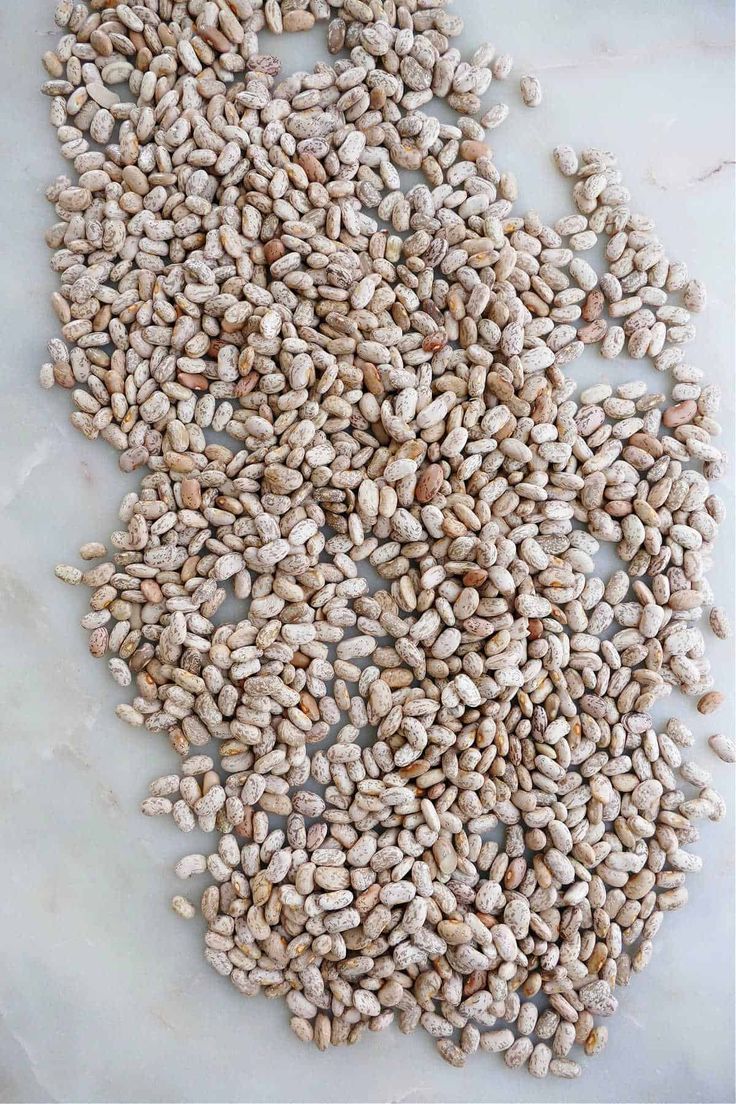

Customs Clearance & Import Regulations for Bulk Iranian Pinto Beans in EU, Middle East & Africa

..

-

Quality Control & Laboratory Testing Standards for Iranian Pinto Beans

..

-

Logistics & Shipping Solutions for Bulk Iranian Pinto Bean Exports

..

-

Minimum Order Quantity (MOQ) & Bulk Pricing for Iranian Pinto Bean Buyers

..

Tags

Quality Control & Laboratory Testing Standards in Iranian Wheat Flour Export

Exporting Iranian wheat flour to global markets requires not just consistent supply but also uncompromising quality and safety standards. For distributors, governments, and food manufacturers importing bulk wheat flour, understanding the quality control and laboratory testing processes in Iran ensures reliable, safe, and market-ready products.

Why Quality Control is Critical in Wheat Flour Export?

Wheat flour is a staple ingredient worldwide. Any compromise in quality can lead to:

• Production inefficiencies

• Consumer dissatisfaction

• Regulatory non-compliance

• Potential health risks

Implementing rigorous quality control ensures that Iranian wheat flour meets international food safety and performance standards, including ISO, HACCP, and Halal certifications.

Key Steps in Quality Control for Iranian Wheat Flour

1. Raw Material Inspection

Quality control begins with the wheat itself. Each batch undergoes:

• Moisture content assessment

• Protein and gluten strength testing

• Foreign matter detection

• Mycotoxin (e.g., aflatoxin) evaluation

These measures guarantee the wheat is suitable for bread, pastry, or specialty flour production.

2. Milling Process Monitoring

Iranian mills implement advanced technology to:

• Maintain uniform particle size

• Achieve consistent extraction rates

• Control temperature and moisture during milling

Continuous monitoring ensures that flour maintains optimal baking performance and shelf-life.

3. Laboratory Testing for Flour

After milling, wheat flour undergoes comprehensive laboratory analysis:

• Moisture content: Prevents spoilage during storage and transport.

• Protein & Gluten content: Determines suitability for bread, pastry, or industrial use.

• Ash content: Indicates the mineral content, important for regulatory compliance.

• Microbiological testing: Detects harmful bacteria and molds.

• Chemical residues: Ensures pesticide levels are within safe limits.

4. Packaging & Storage Verification

Quality control extends to packaging, which protects flour from contamination and moisture. Key checks include:

• Bag integrity (woven polypropylene or laminated sacks)

• Correct labeling and lot tracking

• Storage conditions (temperature and humidity control)

International Standards Applied in Iranian Wheat Flour Export

Iranian wheat flour exports align with global certifications to meet import requirements:

• ISO 22000: Food safety management system.

• HACCP: Hazard analysis and critical control points.

• Halal Certification: Compliance with Islamic dietary laws.

• Organic Certification (if applicable): For organic wheat flour exported to Europe, North America, and Asia.

These certifications provide assurance to importers that the product is safe, consistent, and ready for industrial or retail use.

Benefits for Importers

By sourcing Iranian wheat flour with robust quality control:

• You receive consistent flour performance batch after batch.

• Risk of contamination or spoilage is minimized.

• Compliance with international regulations is simplified.

• Confidence in your supply chain improves, strengthening your brand reputation.

Conclusion

Quality control and laboratory testing are cornerstones of Iranian wheat flour exports. From raw wheat inspection to milling, laboratory testing, and packaging, every stage is closely monitored to meet global safety, hygiene, and performance standards.

For importers, understanding these processes is crucial in selecting the right supplier and ensuring that your bulk Iranian wheat flour shipments arrive safe, compliant, and ready for the market.

Email: tamilaagrifood@gmail.com

Phone / WhatsApp for Inquiries: +989141858935